一、进口四通球阀概述

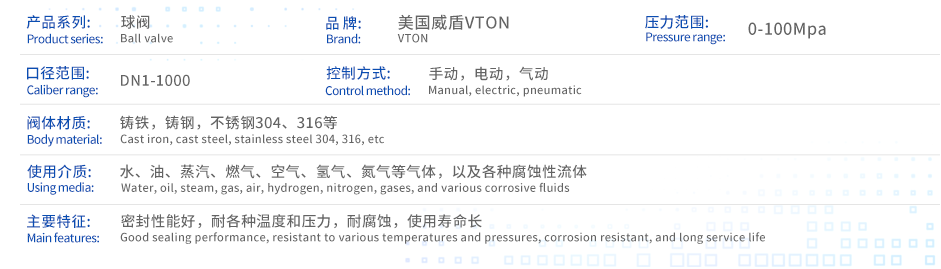

进口四通球阀(美国威盾VTON),Four way flange ball valve,也叫“LL”型四通球阀,四通换向球阀,四通不锈钢球阀,四通法兰球阀,四通螺纹球阀,是由一个四通的球阀阀体,球体内孔为两个L型的通孔,只需操作扳手或执行器将球体转动90度,可同时对两种介质的流向进行切换,既方便又迅速,实现一阀多用的效果的球阀。

Four way flange ball valve (VTON), also known as "LL" type four-way ball valve, four-way reversing ball valve, four-way stainless steel ball valve, four-way flange ball valve, four-way threaded ball valve, is a four-way ball valve body with two L-shaped through-holes inside the ball body. By operating a wrench or actuator to rotate the ball 90 degrees, the flow direction of the two media can be switched simultaneously, which is convenient and fast, achieving the effect of one valve for multiple purposes.

二、进口四通球阀原理

球阀是由旋塞演变而来的,它的启闭件作为一个球体,利用球体绕阀杆的轴线旋转90o实现开启和关闭的目的。球阀不仅结构简单、密封性能好,而且在一定的公称通经范围内体积较小、重量轻、材料耗用少、安装尺寸小,并且驱动力矩小,操作简便、易实现快速启闭。球阀在管道上主要用于切断、分配和改变介质流动方向。“L”型四通球阀只需操作板手或执行器将球体转动90度,可同时对两种介质的流向进行切换,即方便而迅速,实现一阀多用的效果。

A ball valve evolved from a plug, and its opening and closing parts act as a sphere, using the sphere to rotate 90 degrees around the axis of the valve stem to achieve the purpose of opening and closing. Ball valves not only have a simple structure and good sealing performance, but also have small volume, light weight, low material consumption, small installation size within a certain nominal diameter range. They also have small driving torque, simple operation, and are easy to achieve fast opening and closing. Ball valves are mainly used in pipelines to cut off, distribute, and change the direction of medium flow. The L-shaped four-way ball valve only requires the operator or actuator to rotate the ball 90 degrees, and can switch the flow direction of two media simultaneously, which is convenient and fast, achieving the effect of one valve for multiple purposes.

三、进口四通球阀四通球阀应用范围

公称压力或压力级:PN1.0-32.0MPa、ANSI CLASS 150-900、JIS10-20K。

公称通径或口径:DN6~900、NPS 1/4 ~36。

连接方式:法兰、对焊、螺纹、承插焊等。

适用温度:-196℃~540℃。

驱动方式:手动、蜗轮蜗杆传动、气动、电动、液动、气液联动、电液联动。

阀体材料:WCB、ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8(304)、CF3(304L)、CF8M(316)、CF3M(316L)、Ti。选用不同的材质,可分别适用于水、蒸汽、油品、硝酸、醋酸、氧化性介质、尿素等多种介质。

四、进口四通球阀四通球阀结构特点

1、三通流体阻力小,球阀是所有阀类中流体阻力最小的一种,即使是缩径球阀,其流体阻力也相当小。

2、开关迅速、方便,只要阀杆转动90°,球阀就完成了全开或全关动作,很容易实现快速启闭。

3、四通球阀密封性能好。球阀阀座密封圈一般采用聚四氟乙烯等弹性材料制造,易于保证密封,而且球阀的密封力随着介质压力的增加而增大。

4、三通球阀阀杆密封可靠。球阀启闭时阀杆只作旋转运动,因此阀杆的填料密封不易被破坏,而且阀杆倒密封的密封力随着介质压力的增加而增大。

5、三通球阀的启闭只做90°转动,故容易实现自动化控制和远距离控制,球阀可配置气动装置、电动装置、液动装置、气液联动装置或电液联动装置。

6、球阀通道平整光滑,不易沉积介质,可以进行管线通球。

1. Three way fluid resistance is small, and ball valves have the smallest fluid resistance among all valve types. Even for reduced diameter ball valves, their fluid resistance is relatively small.

2. The switch is fast and convenient. As long as the valve stem rotates 90 °, the ball valve can complete the full open or full close action, making it easy to achieve quick opening and closing.

3. The four-way ball valve has good sealing performance. The sealing ring of the ball valve seat is generally made of elastic materials such as polytetrafluoroethylene, which is easy to ensure sealing, and the sealing force of the ball valve increases with the increase of medium pressure.

4. The sealing of the three-way ball valve stem is reliable. When the ball valve is opened and closed, the valve stem only rotates, so the packing seal of the valve stem is not easily damaged, and the sealing force of the valve stem reverse seal increases with the increase of medium pressure.

5. The opening and closing of three-way ball valves only perform 90 ° rotation, making it easy to achieve automatic control and remote control. Ball valves can be equipped with pneumatic devices, electric devices, hydraulic devices, gas-liquid linkage devices, or electro-hydraulic linkage devices.

6. The ball valve channel is flat and smooth, and it is not easy to deposit media, allowing for pipeline ball connection.

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH