一、进口缩径焊接球阀概述

进口缩径焊接球阀(美国威盾VTON),Necking welded ball valve,也叫缩径球阀,小口径焊接球阀,缩径全焊接球阀,是指采用缩径的结构形式,采用碳钢无缝钢管压制成型整体式,以不锈钢为球体,采用全焊接的连接方式,采用碳强化PTFE斜面弹性密封圈负压在球面上,使密封达到零泄漏的球阀。应用于天然气、石油、供热、化工及热电管网等长输管线领域。

Necking welded ball valve (VTON, USA), also known as reduced diameter ball valve, small diameter welded ball valve, or reduced diameter fully welded ball valve, refers to a ball valve that adopts a reduced diameter structure, uses carbon steel seamless steel pipe to press and form a whole, uses stainless steel as the ball, adopts a fully welded connection method, and uses carbon reinforced PTFE inclined elastic sealing ring negative pressure on the spherical surface to achieve zero leakage sealing. Applied in long-distance pipeline fields such as natural gas, oil, heating, chemical and thermal power pipelines.

二、进口缩径焊接球阀特点

(1):由于缩径全焊接球阀阀体是焊接结构,所以阀门重量轻且易于进行绝缘

(2):弹簧负载式PTFE球体的密封可确保在所有应用条件下绝对的严密性

(3):缩径全焊接球阀球体和阀杆都由不锈钢制造带有两个o型环的防飞射阀杆结构保证其严密性,上部容器可更换,工作寿命长

(1) Due to the welded structure of the reduced diameter fully welded ball valve body, the valve is lightweight and easy to insulate

(2) The sealing of spring loaded PTFE spheres ensures absolute tightness under all application conditions

(3) The ball and valve stem of the reduced diameter fully welded ball valve are made of stainless steel, and the anti flying valve stem structure with two O-ring rings ensures its tightness. The upper container can be replaced, and the working life is long

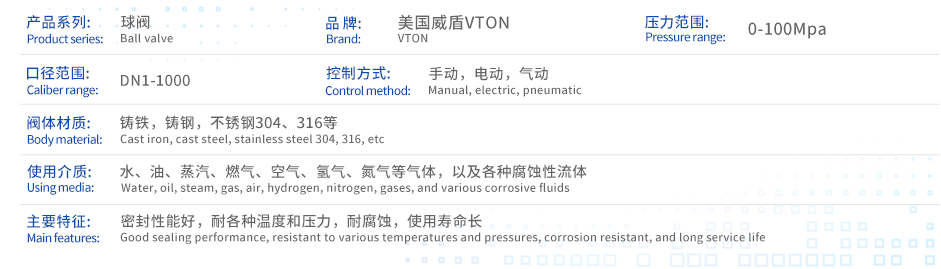

三、进口缩径焊接球阀产品性能参数

1、公称通经:DN15-DN1400 美标1/2” ~ 56”

2、压力范围:PN 16 ~ 420, ANSI Class 150 ~2,500

3、工作温度:-29℃(-20℉) ~ +200℃(392℉)

4、操作方式:手柄、齿轮(垂直/水平)、电动

5、阀体:碳钢ST37, A106-B, STPG 370, A105, ASTM A516-60, A216-WCB

6、球体:不锈钢304或316级别

7、阀座:金属阀座带有聚合物密封圈, PTFE, RTFE, Viton, Nylon, Peek 等。

8、适应介质:供热管道,液化天然气/液化石油气体, 石油化工,钢铁厂,石油/汽油等

四、进口缩径焊接球阀安装说明

1、球阀可安装在任何位置,阀门的任何一端均可作为上游端。

2、在安装阀门时阀球应保持在全开位,否则将导致阀门的损坏。

3、如果在阀门安装时,阀球必须保持在关位,请将暴露在外的阀球表面涂上油脂。这样可保护阀球不被飞溅的焊渣损坏。

4、请勿长时间将阀门放置在半开位状态。

5、对无接管的对焊联端阀门,请切勿在阀球关位安装阀门

6、焊接说明:在预热、焊接或热应力释放时,距焊缝3”以外阀体上的任何点处温度均不能超过400 F(200℃〕。请用测温色笔检验温度。在把球阀最终焊接在管线之前,应用1”宽的保护带盖上阀门密封自三点钟至九点钟区域(阀球与阀座之间的密封和阀座与端部之间的密封〕。这样有助于防止任何杂质落入这个区域,在开工或试压之前,管线系统应清除杂质。

1. Ball valves can be installed in any position, and any end of the valve can serve as the upstream end.

2. When installing the valve, the valve ball should be kept in the fully open position, otherwise it will cause damage to the valve.

3. If the valve ball must be kept in the closed position during valve installation, please apply grease to the exposed surface of the valve ball. This can protect the valve ball from being damaged by splashing welding slag.

4. Do not leave the valve in the half open position for a long time.

5. For butt welded end valves without connecting pipes, please do not install valves in the valve ball position

6. Welding instructions: During preheating, welding, or thermal stress release, the temperature at any point on the valve body 3 "away from the weld should not exceed 400 F (200 ℃). Please use a temperature measuring color pen to check the temperature. Before finally welding the ball valve in the pipeline, cover the valve with a 1" wide protective tape from the 3 o'clock to 9 o'clock area (sealing between the valve ball and the valve seat and the sealing between the valve seat and the end). This helps to prevent any impurities from falling into this area. Before starting work or pressure testing, the pipeline system should remove impurities.

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH