一、进口气动脱硫蝶阀产品概述

进口气动脱硫蝶阀(美国威盾VTON),The pneumatic desulfurization butterfly valve,也叫气动脱硫专用蝶阀,电厂脱硫脱硝蝶阀,不锈钢脱硫蝶阀,是美国威盾专为电厂脱硫脱硝工程而设计,充分考虑了脱硫浆液对阀门的腐蚀和磨损,保证阀板衬里是唯一能够接触到浆液的部件,而其他部件不被石灰石(或石灰膏)浆液腐蚀。因此,阀体和阀杆就不需要采用昂贵的合金(2205)材料,从而大大节约了成本。脱硫蝶阀独特的阀座设计完全把阀体与流体介质隔开,与其他同类阀门比较,它有更佳的阀座牢固方式、就地更换阀座快捷、阀门保持零泄漏、且摩擦小。蝶阀阀板采用高性能合金(2205)材料,有效抵御浆液的腐蚀和磨损。

The Pneumatic Desulfurization Butterfly Valve (VTON), also known as the Pneumatic Desulfurization Butterfly Valve, is specifically designed for power plant desulfurization and denitrification projects. It fully considers the corrosion and wear of desulfurization slurry on the valve, ensuring that the valve plate lining is the only component that can come into contact with the slurry, while other components are not corroded by limestone (or lime paste) slurry. Therefore, the valve body and stem do not require expensive alloy (2205) materials, greatly saving costs. The unique valve seat design of the desulfurization butterfly valve completely separates the valve body from the fluid medium. Compared with other similar valves, it has a better way to secure the valve seat, quick on-site replacement of the valve seat, zero leakage of the valve, and low friction. The butterfly valve plate is made of high-performance alloy (2205) material, which effectively resists the corrosion and wear of the slurry.

二、进口气动脱硫蝶阀产品特点

1、气动脱硫蝶阀主要结构由阀体,阀瓣,阀座,阀杆及传动操作机构等部件组成,阀座采用可脱卸构造,并可根据不同介质的物理化学特性,选用相应的耐高温,耐低温,耐腐蚀,耐光,耐老化材质。

2、气动脱硫蝶阀采用中线型结构无偏心设计,具有显著的操作扭矩低的特征,配置电动装置时的经济性显著;

3、气动脱硫蝶阀采用衬胶结构,蝶板圆周形密封面精密加工至较高的光洁度,对橡胶阀座的摩擦系数极低,阀门使用寿命较长;

4、气动脱硫蝶阀阀板密封面流态特性呈线性状态,具有较小的流阻系数,阀门流阻小;

5、气动脱硫蝶阀独特设计的模压橡胶阀座具有极佳的均衡性和支撑性。

1. The main structure of pneumatic desulfurization butterfly valve is composed of valve body, valve disc, valve seat, valve stem, and transmission operating mechanism. The valve seat adopts a detachable structure, and corresponding materials that are resistant to high temperature, low temperature, corrosion, light, and aging can be selected according to the physical and chemical properties of different media.

2. The pneumatic desulfurization butterfly valve adopts a medium linear structure with no eccentricity design, which has the significant feature of low operating torque and significant economic benefits when equipped with an electric device;

3. The pneumatic desulfurization butterfly valve adopts a rubber lined structure, and the circumferential sealing surface of the butterfly plate is precisely machined to a high smoothness. The friction coefficient of the rubber valve seat is extremely low, and the valve has a long service life;

4. The flow characteristics of the sealing surface of the pneumatic desulfurization butterfly valve plate are linear, with a small flow resistance coefficient and a small valve flow resistance;

5. The uniquely designed molded rubber valve seat of the pneumatic desulfurization butterfly valve has excellent balance and support.

三、进口气动脱硫蝶阀技术参数

公称通径:DN50-600(mm)

公称压力:1.0-1.6MPa

连接方式:对夹、法兰

阀体材料:HT200、QT400、WCB、不锈钢

阀板材料:1.4529 ; 双相不锈钢2507

阀座:EPDM、PTFE、F46

安装执行器及附件:气动执行器、手操机构、电器定位器、限位开关、电磁换向阀

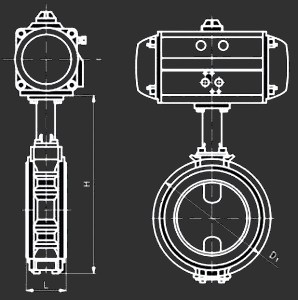

四、进口气动脱硫蝶阀外形尺寸

单位:mm

通径 DN | L | H | 1.0MPa | 1.6MPa | 气动执行器选配 (双作用,气源5bar) | |||||

D | D1 | n-d | D | D1 | n-d | |||||

50 | 42 | 197 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | VTG52 | VTA52 |

65 | 44 | 217 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | VTG63 | VTA63 |

80 | 44 | 232 | 200 | 160 | 8-18 | 200 | 160 | 8-18 | VTG63 | VTA75 |

100 | 50 | 266 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | VTG83 | VTA83 |

125 | 56 | 293 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | VTG110 | VTA105 |

150 | 56 | 319 | 285 | 240 | 8-23 | 285 | 240 | 8-23 | VTG110 | VTA105 |

200 | 60 | 389 | 340 | 295 | 8-23 | 340 | 295 | 12-23 | VTG127 | VTA127 |

250 | 68 | 456 | 395 | 350 | 12-23 | 405 | 355 | 12-28 | VTG140 | VTA140 |

300 | 78 | 520 | 445 | 400 | 12-23 | 460 | 410 | 12-28 | VTG160 | VTA160 |

350 | 78 | 587 | 505 | 460 | 16-23 | 520 | 470 | 16-28 | VTG190 | VTA190 |

400 | 102 | 649 | 565 | 515 | 16-28 | 580 | 525 | 16-31 | VTG210 | VTA210 |

450 | 114 | 713 | 615 | 565 | 20-28 | 640 | 585 | 20-31 | VTG240 | VTA240 |

500 | 127 | 786 | 670 | 620 | 20-28 | 715 | 650 | 20-34 | VTG270 | |

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH